Shanghai KUNGKING Industrial Co., LTD

Business consulting: Andy 13917974131

Contact number: 021-39531206

E-mail: 13917974131@126.com

Address: Workshop in Area 8, No. 558 Xinye Road, Qingpu Industrial Park, Shanghai, China

How can waterproof and permeable fabric be permeable to moisture?Waterproof and moisture permeable fabric is a kind of high-tech and unique functional fabric, in which water does not soak into the fabric under a certain pressure, but the sweat emitted by the human body can be transmitted to the outside world in the form of water vapor, so as to avoid the accumulation and condensation of sweat between the body surface and the fabric to maintain the comfort of clothing.Waterproof is not a problem for ordinary fabric workers, the key is how to achieve moisture permeability.Let's take a closer look at the types of waterproof and moisture permeable fabrics.One, through the fiber to achieve moisture permeability1. Venter fabric.The earliest waterproof breathable fabrics were the famous Ventile fabrics.Designed in the 1940s by the Shirley Institute in England, it is a high-count, low-twist, pure cotton yarns of Egyptian long-staple fabric with high density, heavy and flat weave. It was originally used in the cold and immersion suits of British Air Force pilots during World War II.When the fabric is dry, the gap between the warp and weft yarns is large, about 10 microns, providing a highly moisture permeable structure;When rain or water falls on the fabric, the yarns expand, reducing the gap between the yarns to 3-4 microns. This closed-hole mechanism is combined with a special water-repellent finish to ensure that the fabric is not further penetrated by rain.At present, this kind of fabric has been replaced by other waterproof and moisture permeable fabrics.2. Coolmax fabrics.International large companies such as Dupont and Toray of Japan have studied the way of creating pores inside the fiber to expel sweat from the body, that is, the hygroscopic and sweat draining fabric on the market.This kind of fiber production technology is concentrated in the hands of such large international companies, the price is relatively high, difficult to become the mainstream market.Second, through the coating to achieve moisture permeabilityA variety of coating agents with waterproof and moisture permeability functions are applied on the surface of the fabric by direct dry coating, transfer coating, foam coating, phase inversion or wet coating (solidification coating), etc., so that the surface pores of the fabric are closed or reduced to a certain degree by coating agents, thus obtaining water resistance.The moisture permeability of the fabric is obtained by the interaction between the hydrophilic groups in the coating agent and the water molecules by means of hydrogen bonds and other intermolecular forces, which adsorb the water molecules on the high humidity side and transmit them to the low temperature side.The coating fabric is widely used because of its low price and certain moisture permeability.However, due to its poor waterproof and moisture permeability and unsatisfactory hand feel, the market share is gradually decreasing.The wet transfer coated fabric developed now makes the coated fabric glow with a new machine. It not only has high physical indexes such as waterproof and moisture permeability, but also can be treated with 100% Teflon. The washing fastness can reach more than 25 times, and the handle is also very good.Third, through laminating waterproof moisture permeability film to achieve moisture permeability1. The diameter of water vapor molecules in PTFE film is 0.0004 microns, while the diameter of light fog with the smallest diameter in rain water is 20 microns, and the diameter of drizzle is as high as 400 microns. If the film with pore diameter between water vapor and rain water can be produced, isn't it possible to be both waterproof and permeable?GORE of the United States became the first company to produce the film using polytetrafluoroethylene (PTFE), which was laminated with a fabric to produce gore-Tex.However, due to PTFE's very strong chemical inertia, there are few materials that can press it well with other fabrics, and the first generation fabrics have very poor fastness.Later, through continuous efforts, through other hydrophilic film sublayer together into a composite film, and on the film for special treatment, the fastness greatly improved.It is generally believed that the water pressure of Gore-Tex fabric can reach 10000mm, and the water pressure drops significantly after 6-7 times of washing.The moisture permeability can be as high as 10000g/ SQM * 24Hrs, but this is not a value that can be achieved with the newly made fabric. Several times of washing is needed to remove part of the glue. The available pores increase and the moisture permeability increases.TPU film TPU is short for thermoplastic polyurethane film and belongs to non-porous hydrophilic film.Because the film itself has no pores, it is naturally waterproof, but it also keeps the fabric windproof and warm.Moisture permeability is mainly realized through its hydrophilic characteristics. Depending on the difference of steam pressure inside and outside the clothes, the steam is transferred from the place with high pressure to the place with low pressure, thus realizing the function of moisture permeability.

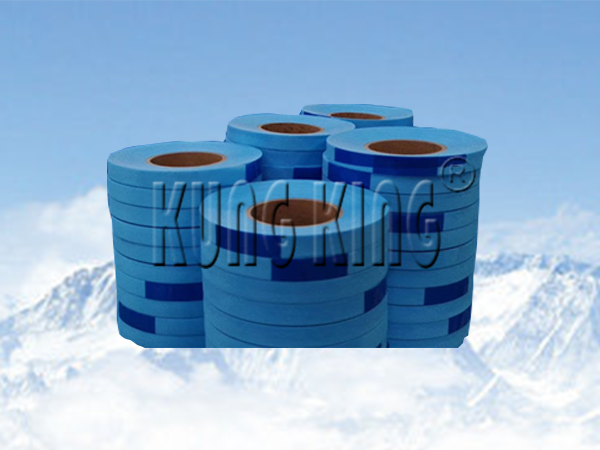

With TPU hot melt adhesive as raw materials for the production of hot melt adhesive film series in the hot glue industry has been popular, become a kind of new composite material, and can be used in different industries, bringing the Gospel to more and more enterprises, it is a revolution of industrial production, is a kind of inevitable trend of development of hot melt adhesive film industry!The scale of hot melt film market in Mainland China has become the largest market of hot melt adhesive in the world several years ago.Although the scale of the hot melt adhesive market in Mainland China is large, its annual growth rate is still the fastest in the world.With the rapid development of domestic industry, textile industry, clothing industry and so on, the demand for thermal bonding process is also increasingly strong. Hot-melt adhesive film occupies a very important position in the whole composite market!In the current situation, hot melt film has a firm foothold, but the development will always meet a bottleneck.There are many problems to be solved in the reproduction of hot melt film, such as environmental protection requirements, applicable industry, such as quality control and so on.This series of problems need to be solved!First, let's talk about environmental protection!Hot melt glue enterprise development tuyere is environmental protection, as people's living standard rises with each passing day, people also is higher and higher to environmental protection quality requirement.In recent years, China has carried out around the voc emission control and environmental protection situation increasingly tightens, people environmental protection consciousness has increased, the related legal policy is also more and more strict, the domestic environmental situation is very serious in our country, so the hot melt adhesive of environmental protection should be as an important turning point in the enterprise development, enterprise only for positioning, accurate, can grasp the opportunity and to win.Secondly, the rapid development of hot melt adhesive industry forces innovation, only constant innovation can keep up with the pace of the industry, innovation can be from the quality, differentiation, service and so on.I believe that hot melt film in the near future will be used in more and more industries to go!